.ANTI BACKLASH SPUR GEARS |

Backlash – A “play” between gears

Backlash, sometimes called “play” is a clearance or lost motion in a mechanism caused by gaps between the parts, that is necessary for gearing to function properly. Still, most machine designers think backlash is not desirable as it disturbs their ideal design. However, proper backlash is necessary to prevent damage to the gears caused by a lack of lubrication. In addition, as every gear has deviations, noise and oscillation happen when the gears rotate. Backlash is necessary to reduce noise and oscillation caused by gear deviations, as it helps absorb some of such deviations. (PDF : “Backlash” from KG Technical Data)

On the other hand, demands for zero-backlash mechanisms still exist. To meet such demands, we created our Standardized Anti-backlash spur gear series, which although cannot completely remove the backlash, greatly minimize it. Our Anti-backlash spur gears adopt a time-Proven mechanism with built-in springs between two gears that pull each other in order to pinch the mating gear like a scissor. When rotated, the direction of the gear is reversible since the springs of the Anti-backlash spur gear can continue to maintain suitable torque by pinching the mating gear. If interference occurs due to gear quality, the Anti-backlash spur gear can help absorb the interference by stretching the spring mechanism between gear A and B while engaged with the mating gear.

Anti-Backlash Spur Gear Design – 3D CAD models and 2D CAD drawings

You can verify the dimensions of our standard Anti-Backlash Gears through our PDF catalog or our Newly implemented Gear Selector provided by Part Community. Free CAD data is available on our website. Click on the logo below to access the Gearbox Selector.

Quotation of Standard Anti-Backlash Spur Gears

Please request your Quotations for Anti-Backlash Spur Gears through our “Request For Quotation” page.

Anti-Backlash Spur Gear Modification

We can customize our standard Anti-Backlash Spur Gears to suit your specific applications, please consult with us. We are offering gear customization services. For more details and examples of modifications, please visit our “Gear Modification” page.

Precaution of Usage

Please refer to the following link for precautions before using KG Anti-Backlash spur gears.

(PDF : “Precaution of usage for Anti-backlash spur gears” from KG Gear Catalog)

| NSU TYPE | NS TYPE | NS TYPE |

|

|

|

| Material (ISO) : X5CrNi18-10 Module : 0.5 Number of teeth : 60 – 120 |

Material (ISO) : AlMg5 Module : 0.5 – 1.0 Number of teeth : 60 – 120 |

Material (ISO) : C45 Module : 0.5 – 1.0 Number of teeth : 60 – 120 |

|

Teflon coated to prevent scuffing and provide a smoother motion.

|

Teflon coated to prevent scuffing and provide a smoother motion.

|

Nitrite treated to prevent scuffing and provide a smoother motion.

|

| PDF CATALOG | PDF CATALOG | PDF CATALOG |

| NSG TYPE | ASG TYPE | |

|

|

|

| Material (ISO) : 34CrMo4 or 42CrMo4 Module : 0.5 – 1.0 Number of teeth : 60 – 120 |

Material (ISO) : 34CrMo4 or 42CrMo4 Module : 1.0 – 2.0 Number of teeth : 30 – 120 |

|

|

Precision ground teeth for a more accurate positioning , less oscillation and lower noise at high RPM.

|

Suitable for higher torque and higher RPM applications when compared to our spring type anti-backlash spur gears.

|

|

| PDF CATALOG | PDF CATALOG |

How our Anti Backlash Spur Gear mechanism works

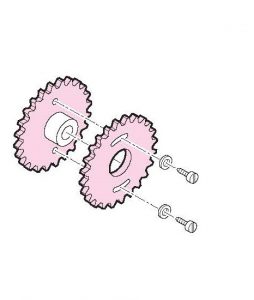

| ASG TYPE |  |

For our ASG series, the operation method works by loosening the setting bolts to assemble our ASG series gear with the matching gear and then adjusting gears A and B in order to reduce backlash to a minimum. The ASG series works best for applications that require only a minimal backlash adjustment, Higher torque applications and that are matched with high quality gears. |

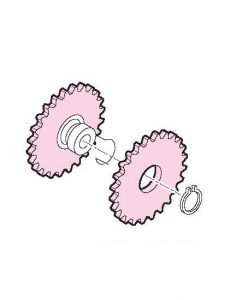

| BS TYPE |  |

Our BS type gears use a Circular Arc Spring placed between gear A and B in order to eliminate the backlash. BS series gears are recommended for applications that require a lower amount of torque. |

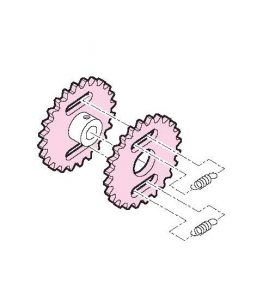

| BW TYPE |  |

Our BW type gears use a spring suspension method placed between gears A and B. The tension of the spring will allow them to slip relative to each other in order to eliminate the backlash by engaging with the matching gear and holding it in a scissor like motion. |