.GEAR MODIFICATION |

Reliable service

We have expanded our standard product range to more than 5,000 items. However, even our diverse product range is not enough to fulfill each and every customer’s demands. Therefore, we are also providing gear modification services. If you can not find the specific gears you require in our catalog, we can provide modification services for our standard gears and gearboxes.

Advantages of gear modification

Compared with customized gears, modified gears have some advantages..

・Shorter lead time – In most cases gear modification services offer shorter lead times when compared with fully customized products.

・Easy to design – You do not need to calculate gear dimensions by using complicated formulas.

Example of Modification

You can see some examples of Modifications below.

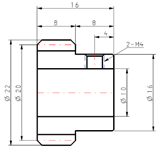

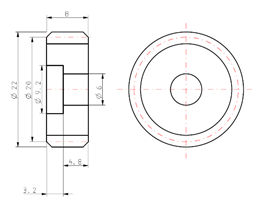

1,Expansion of the bore diameter and addition of set screw hole

Precautions :The bore diameter should not be bigger than 60 to 70% of the Hub diameter as to avoid excessive thinning of the material.

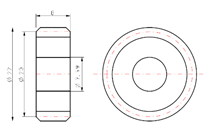

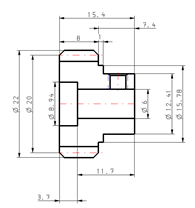

2,Addition of a counter bore

Precautions:When machining the counter bore, the creation of a machining clearance groove or relieve will be necessary.

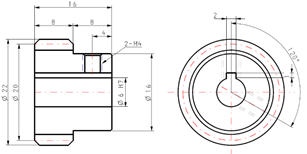

3,Step machining of the Hub.

Precautions:When requesting step machining for the Hub, please keep in mind that making the hub diameter might generate problems when machining and during usage of the gear.

4,Key way and Set screw hole addition.

Precautions:When requesting additional set screw holes or the machining of a key way, we strongly recommend selecting JIS standard sizes in order to accelerate the process and avoid unnecessary tooling charges.

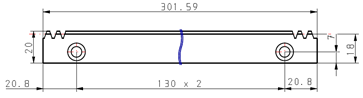

5,Additional machining on our racks.

Precautions:When requesting additional machining of set holes in our racks, please avoid setting said holes to close to the root of the teeth.

NO MOQ

We offer our gear modification services without minimum order quantities. If you require a quotation, please contact us with the details of the modification through our “Request For Quote” page. In some cases, we may request drawings if the modification is too complicated.

・We do not perform modifications to the face width of any gear due to the fact that this type of modifications generate a big amount of burrs. If you require a thinner face width, we can quote a customized gear.

・Accuracy grade may decrease after modification, especially when modifying the bore.

・We may not able to modify some items because of its shape, tolerance and accuracy grade.

・In case of lack of original standard items, we may take additional lead time to complete modification.